In today's fast-paced industrial landscape, achieving optimal mixing within reactors and vessels is crucial for ensuring product quality and operational efficiency. Industries such as pharmaceuticals, chemicals, food and beverage, and energy rely on precise mixing processes to meet their quality standards and production goals. Computational Fluid Dynamics (CFD) is a transformative tool that revolutionizes our understanding and optimization of these mixing operations.

The Power of CFD

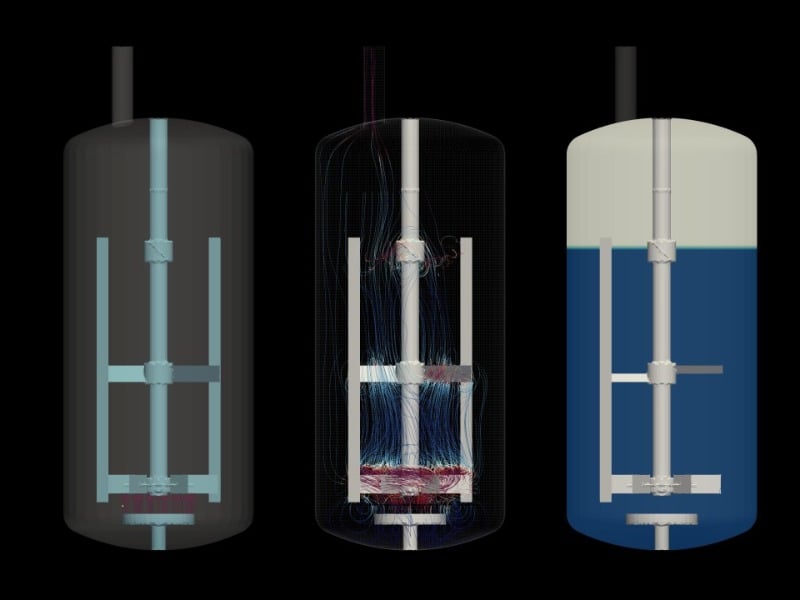

Computational Fluid Dynamics (CFD) involves the use of numerical methods and algorithms to simulate fluid flow, heat transfer, and all related phenomena. By simulating the behavior of fluids, CFD allows engineers to visualize complex flow patterns, predict turbulence, and optimize mixing processes in a virtual environment before implementing them in the real world.

Key Benefits of CFD in Industrial Mixing

Applications Across Industries

Pharmaceutical Industry

In pharmaceuticals, uniform mixing is essential to ensure consistent drug formulations and dosage uniformity. CFD simulations help design processes that achieve the required homogeneity, which is crucial for both efficacy and safety.

Chemical Industry

For chemical processes, CFD aids in optimizing reaction kinetics and mixing, ensuring thorough mixing of reactants. This can lead to increased yields, reduced reaction times, and lower production costs.

Food and Beverage

In the food and beverage industry, CFD is used to optimize mixing processes to ensure consistent texture, flavor, and quality of products. This is vital for maintaining product standards and meeting consumer expectations.

Energy Sector

CFD assists in the design and optimization of processes such as combustion and thermal management, leading to more efficient energy production and reduced emissions. It is also used in the design of equipment like turbines and heat exchangers.

Tools of the Trade

Two of the most popular tools used for CFD simulations are OpenFOAM and ANSYS Fluent. Each offers unique features and capabilities:

Driving Innovation with CFD

By leveraging the power of CFD, engineers can push the boundaries of process optimization and drive innovation across industries. The ability to simulate and analyze fluid dynamics in detail allows for the development of tailored solutions that address specific operational needs and challenges, leading to better performance and efficiency.

Conclusion

As industries continue to evolve, the role of CFD in optimizing mixing processes becomes increasingly important. By adopting advanced simulation tools like OpenFOAM and ANSYS Fluent, companies can achieve greater efficiency, product quality, and sustainability.

Get in Touch

Interested in exploring how CFD can optimize your mixing processes? Connect with us to discover customized solutions that drive efficiency and innovation.

Contact

+358413138387